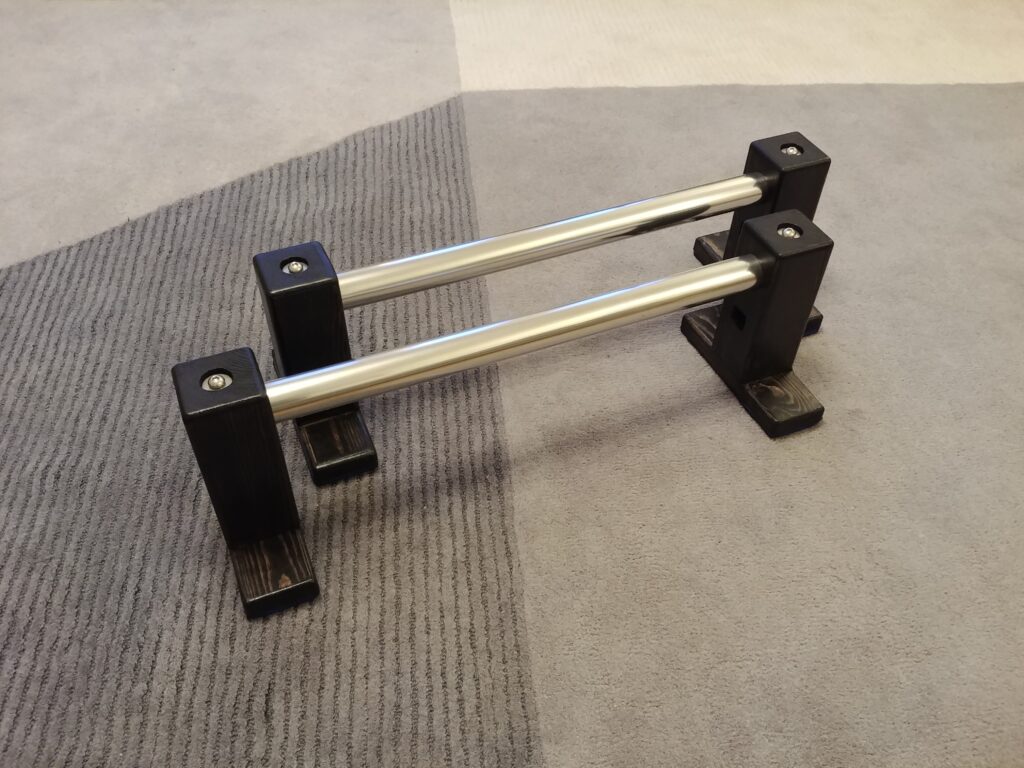

Parallettes (09/2015)

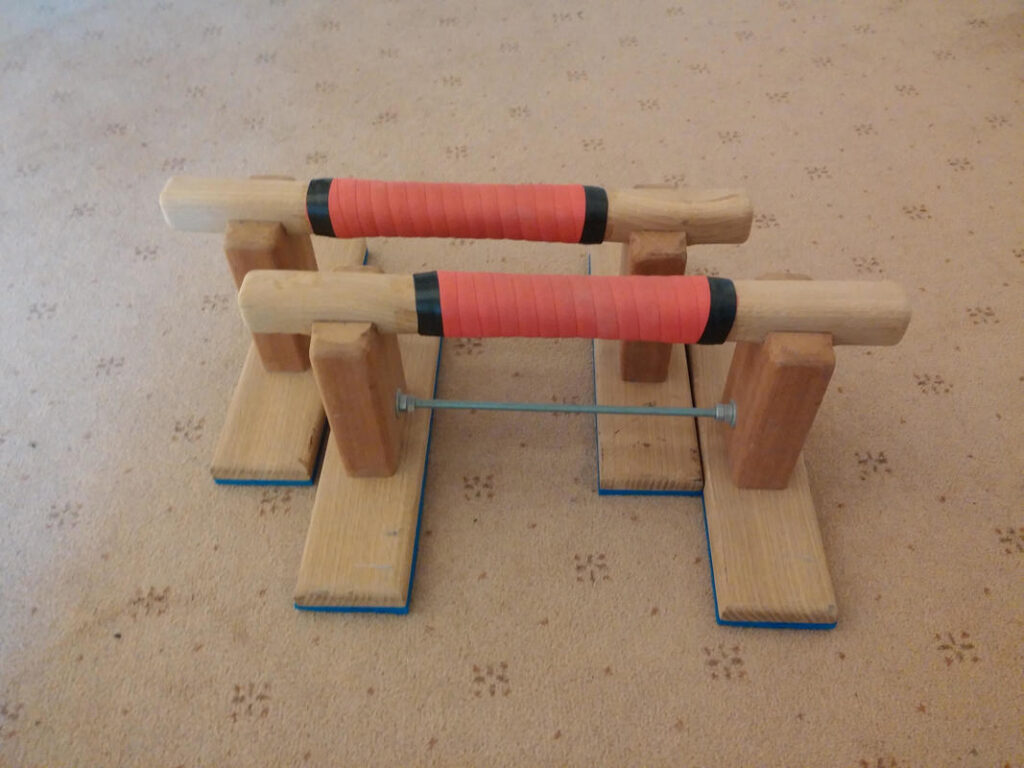

I first heard about parallettes whilst watching the Buff Dudes YouTube channel and just had to make myself some. I did a bit of reading around the subject of parallettes and had a look around to see what I had in my garage; by the end of the weekend this is what I had managed to make:

My local timber yard offers a cutting service, so for an easy life I took advantage of it. I marked up all of the joints at the same time; it is faster to work this way, particularly if you are making a few of something. The 1 1/2″ (38.1mm) diameter aluminium tube was sold in 600mm lengths, so that did not require any further cutting. I bought enough tube to make three pairs of parallettes to hit a price break, and marked up a couple of extra uprights so that if i needed to make the other pairs I could take my measurements quickly from these.

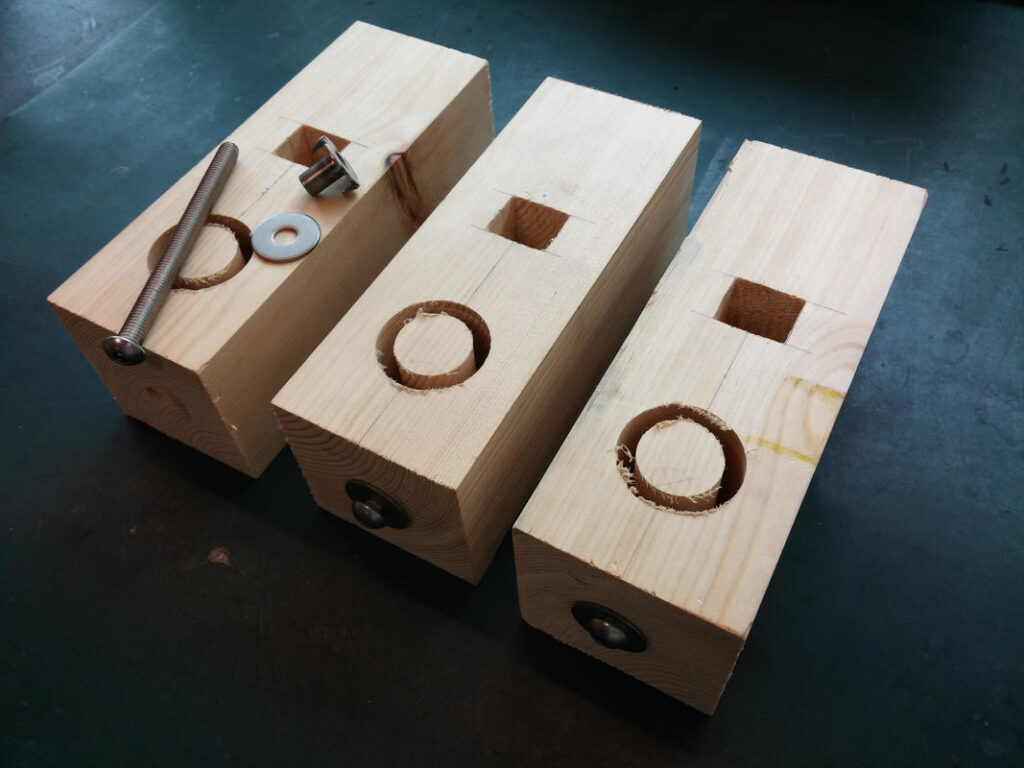

A router was used to remove the bulk of the waste from the stopped mortises. A chisel was then used to square the corners.

Stopped holes to locate the tubes were cut on a CNC mill. I decided to fix the tubes to the uprights via a long bolt down the centre of the upright, through the tube and screwed into a T nut. Stopped mortises were cut out to allow the T nuts to be placed into the upright and counterbores were routed in the top to allow the button head bolts to sit flush.

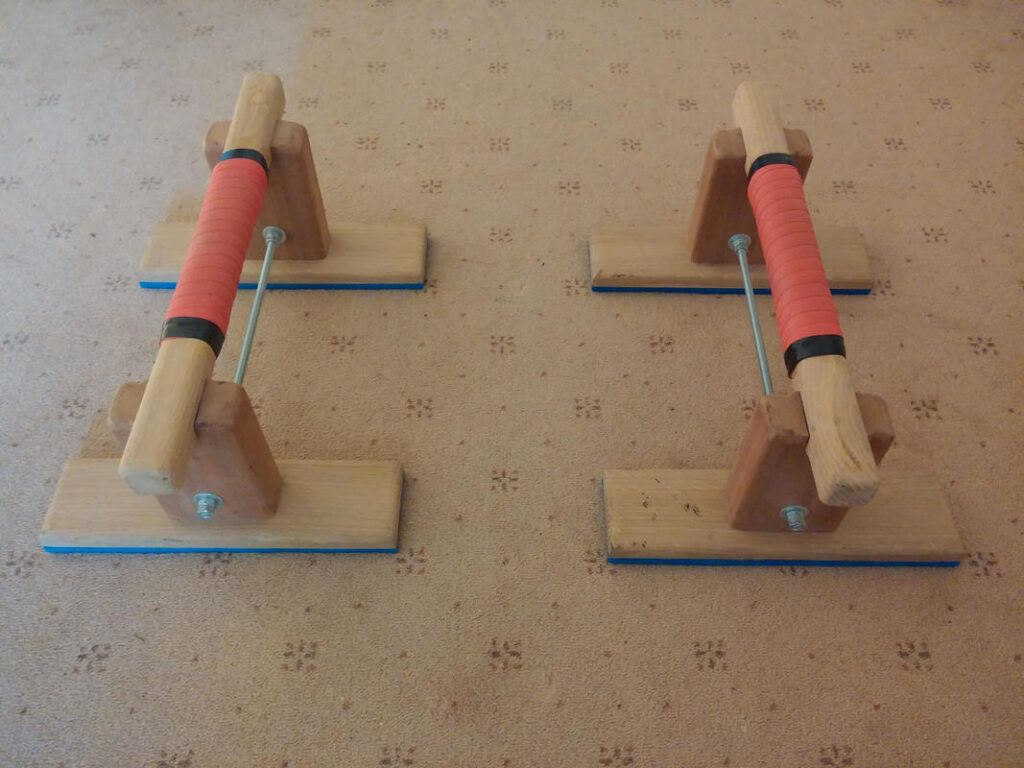

The tenons were then routed out of the bottom of the uprights and finished with a chisel. The joints were glued and clamped and left overnight. Once the glue had set, the uprights were given a once over with a 1/4″ round over bit and then sanded.

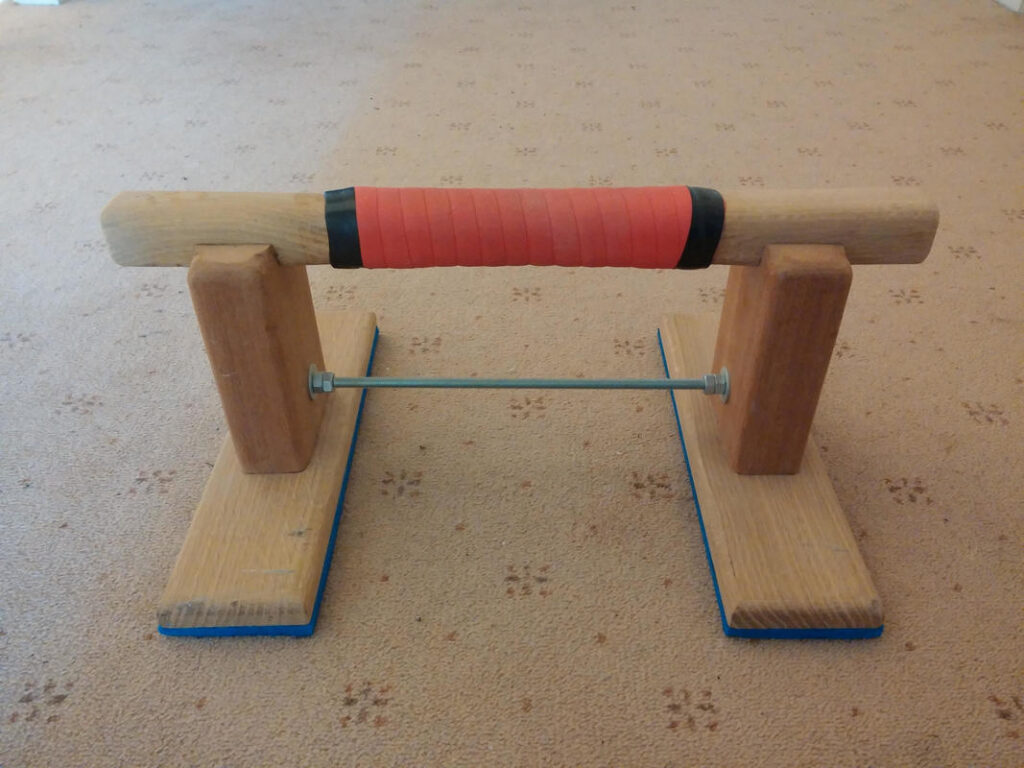

I glued camping mat to the feet as I did in my first pair to protect hard flooring against scratches. I dyed the feet with Rustins black wood dye and then gave them a couple of coats of No Nonsense danish oil to finish and protect them. Finally, I polished the aluminium tubes by first using wet & dry paper, working up the grades and finishing off with some Silvo Tarnish Guard metal polish wadding.

These parallettes are far better than my first attempt. The top of the bar is 170mm off the ground, and there is 500mm of available rail. They are extremely sturdy with no noticeable flex, and only one allen key is needed to assemble/disassemble. The 1 1/2″ tube is a comfortable size to hold and feels so much better than the grip tape. I was worried about the level of grip on the polished aluminium tube but I have not had any issues with hands slipping off the bar. Overall, I’m very happy with how these parallettes turned out, I just need to make time to use them…